O Ring Durometer Chart

The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application.

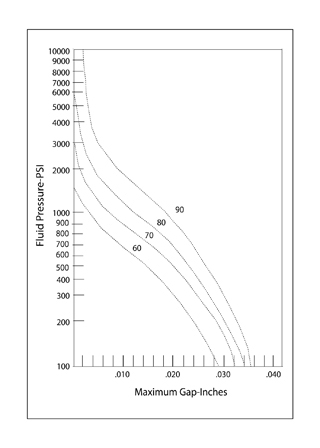

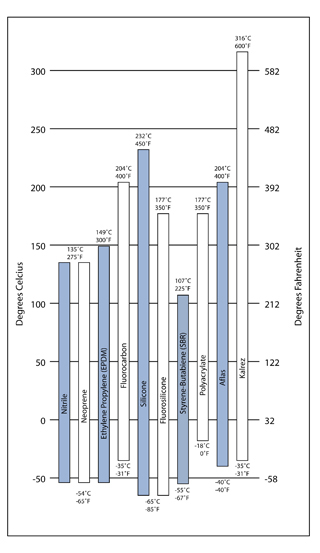

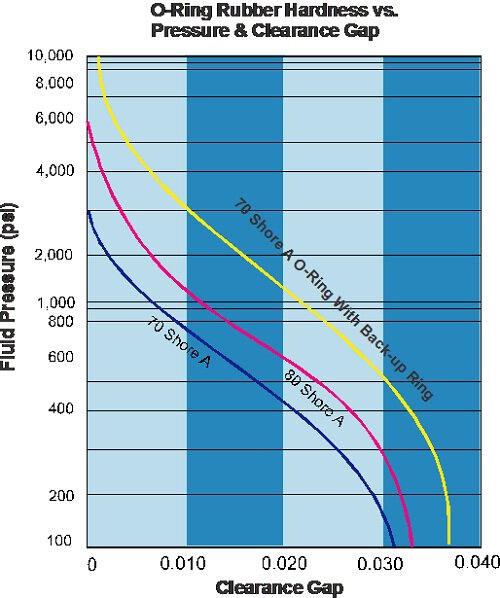

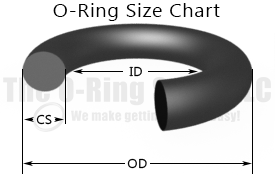

O ring durometer chart. O ring size chart o ring cord stock osk assorted o ring kits osk o ring repair kits osk hydraulic seal kits osk air nailer o ring kits o ring lube o ring tools as568 o rings inch metric o rings mm osk pool spa pump o rings hydraulic seals inch o ring glue thread sealant vulcanized o rings o ring splice kits tools hydraulic seals metric oil. Wherever possible 70 durometer hardness should be used as it offers the best combination of properties for most o ring applications. Softer compounds stretch easier and seal better on rough surfaces. Excessive clearance and or pressure can result in sealextrusion and failure.

Tolerances should be considered for the o ring and the. The hardness of rubber compounds is measured by shore a durometer. For most applications compounds having a durometer hardness of 70 to 90 is the most suitable compromise. This silicone 70 durometer specifications chart will help you determine if these silicone material properties will be compatible with your rubber or o ring seal application.

In the o ring industry another hardness scale is used due to the curved surface of the o ring cross section causing problems with accurately reading shore a. Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a. The o ring store llc. Generally most rubber materials fall under the rubber durometer scale of shore a.

Consider use of back ups or product selection with large gaps or pressure. Harder materials like 70 75 or 90 durometer compounds offer greater resistance to extrusion. Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a. The higher the durometer number the harder the compound.

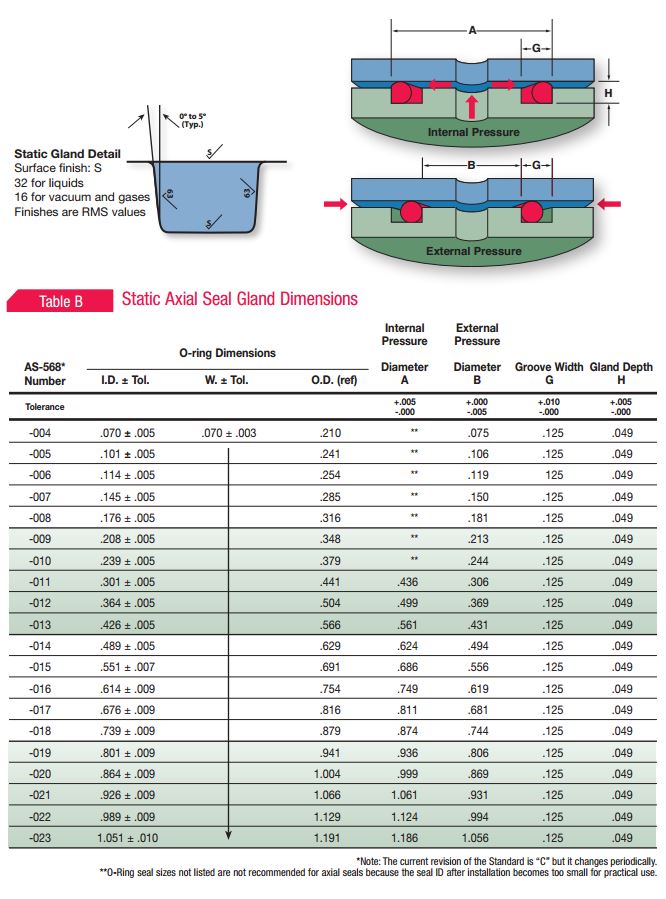

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications. This as568 o ring chart is a sae size standard for o rings and shows as568 rev b or as568b o ring sizes which supersedes as568 rev a or as568a o ring dimensions. O ring application pressure vs. We have millions of as568 o rings in stock which can be purchased easily through our o rings online store.

Generally most rubber materials fall under the rubber durometer scale of shore a. We can change the formulation of the rubber so that the specifications meet your needs. For specimens that are too thin or provide too small an area for accurate durometer readings micro hardness testing is recommended. The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application.

In dynamic applications the hardness of the o ring is doubly important because it also affects both breakout and running friction. The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application.