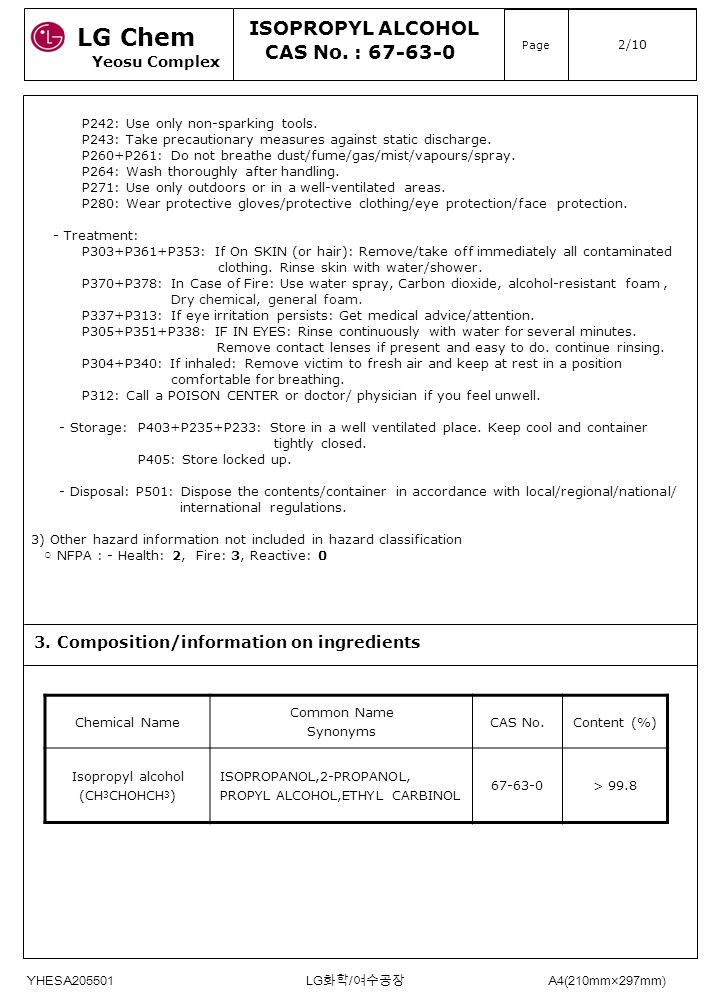

Non Sparking Tools Material Composition

In order to increase work place safety safety experts recommend that you store your non sparking tools separately from your standard tools.

Non sparking tools material composition. Non sparking tools are made of materials that do not contain iron non ferrous metals and therefore the risk of a spark being created while the tool is in use is reduced. Sparkless non sparking tools are most suited for potentially explosive environments. Ampco meets this need by offering a variety of standard or custom kits to meet your specific needs. Copper beryllium alloy sparkless non sparking tools are most suited for application purposes in potentially explosive environments most of our non sparking tools are forged after casting to achieve better quality performance attractive finish.

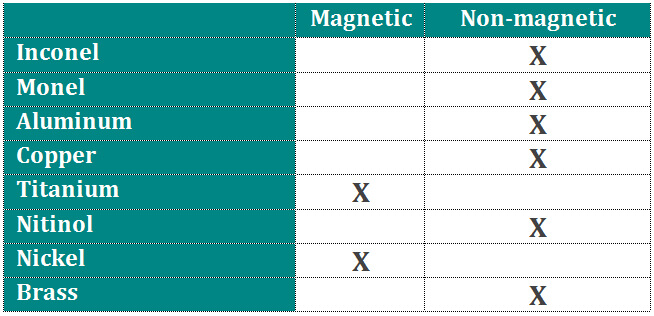

Most of our non sparking tools are forged after casting to achieve better quality performance attractive finish. Material of composition. Two types of hazards are associated with tools manufactured of either material. Non sparking tools are made of materials that do not contain iron non ferrous metals such as brass bronze monel metal copper nickel alloy copper aluminum alloys aluminum bronze or copper beryllium alloys beryllium bronze and therefore the risk of a spark being created while the tool is.

Most of our non sparking tools are forged after casting to achieve better quality performance attractive finish. Non sparking wrenches double open ended non sparking wrenches open end non sparking spanners aluminum bronze alloy. Non sparking tools are characterized by their lack of ferrous metals steel and iron which means they don t cause sparks that could. Ignition by friction with impact on each other or on other materials such as steel or concrete in which an ordinary mechanical or frictional spark is generated.

Non sparking tools protect against both fire and explosion in environments that may contain flammable liquids vapors dusts or residues. However they each are designed to prevent specific dangers and shouldn t be confused. It has excellent metalworking forming and machining properties it has many specialized applications in tools for hazardous environments. Beryllium copper becu also known as copper beryllium cube beryllium bronze and spring copper is a copper alloy with 0 5 3 beryllium and sometimes other elements.

Non sparking marking tool material of composition. Mix match there is no catch. Aluminium bronze spark less non sparking tools are most suited for. Application purposes in potentially explosive environments.

Non sparking tools are made up of non ferrous materials such as alloys of copper brass bronze nickel beryllium and aluminium. Beryllium copper combines high strength with non magnetic and non sparking qualities. Both sparking and non sparking materials can cause ignition. Hand tools with a non ferrous composition are relatively softer as compared to their ferrous counterparts.